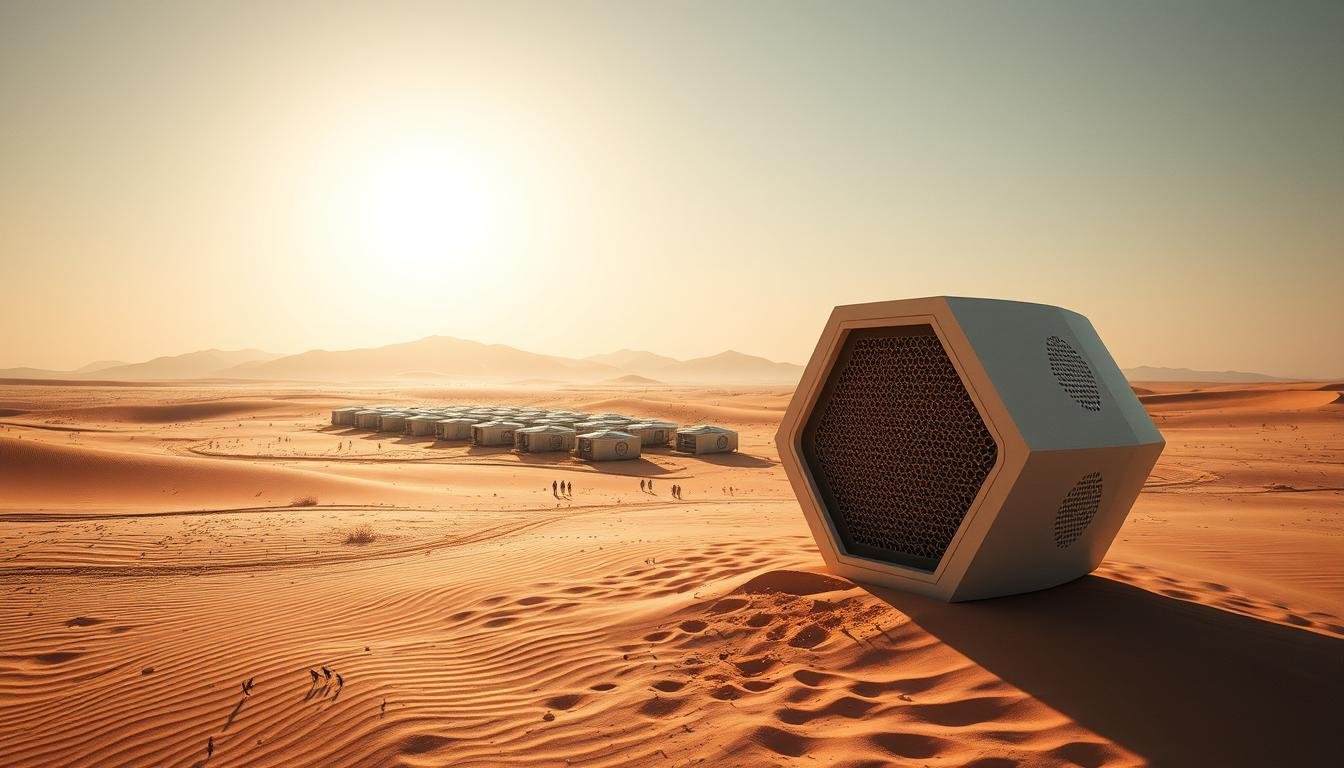

Managing colonies in arid U.S. regions demands a clear approach that balances thermal control, moisture management, and low disturbance. Hot, dry conditions raise metabolic load and make traditional wooden boxes struggle with radiant heat and chronic dehydration.

Two complementary paths work well: a natural-style Warre management that favors foundationless comb and small boxes, and an engineering-first option that boosts insulation and airflow control. Field studies — including work in the Negev — show optimized insulated units can cut heat loss dramatically and improve yields, survivability, and population growth.

Practical choices matter: shade placement, controlled ventilation, and reliable water reduce colony stress. Later sections will compare materials like EPS vs. wood, outline wall thickness targets, and explain continuous brood geometry and single-entrance setups.

For an in-depth look at Warre methods and natural management, see this guide: Warre beekeeping overview.

Key Takeaways

- Thermal optimization and moisture control are critical to colony health.

- Natural Warre methods reduce disturbance but may lower immediate yields.

- Insulated, engineered boxes can multiply harvests and cut feeding needs.

- Site choices — shade, ventilation, water — support long-term success.

- Later sections will cover materials, wall thickness, and harvest steps.

Understand Desert Constraints Before You Build

Start by facing the core stresses your bees will meet in hot, arid regions. Map daily peaks: long stretches of high temperature, harsh solar load, and very low relative humidity. These forces test how hives shed heat and how colonies hold moisture.

Heat, aridity, and thermal stress: what your bees experience daily

Brood must sit near 35°C. When ambient temps climb, the usual heating problem flips into cooling and moisture loss. That still drains the colony’s energy as workers fan and water-balance the nest.

User intent and goals: durability, honey production, and colony health in hot, dry climates

Good control reduces constant fanning and broken foraging cycles. Poor or leaky units force higher metabolic costs and lower honey stores.

“Predictable shading, short inspections, and planned seasonal actions cut stress and loss.”

Decision inputs include expected temperature ranges, sun exposure, wind, dust, forage gaps, and water access. Note that simple insulation add-ons to traditional wood often yield only 15–30% improvement and rarely fix systemic thermal issues.

- Time and practical experience shape inspection cadence and intervention timing.

- Site choice and shading pair with technical choices to deliver reliable outcomes over years.

Hive design for desert environments: materials, geometry, and thermal optimization

Thermal performance and material choice set the foundation for any successful hot‑climate hive. Choose bodies and wall systems that lower conductive heat gain and keep the brood zone near 35°C with minimal worker effort.

Material choices: EPS versus wood

EPS outperforms wood in conductivity by roughly 5–10x. Lab tests show optimized insulated units at ~0.01 W/dm²·°C versus 0.07 W/dm²·°C in a standard Dadant wood box. That ~7x improvement stabilizes brood temperatures and reduces colony energy spent on cooling.

Wall thickness and thermal mass

Select wall thickness between 30–70 mm based on local heat load. Thicker walls help in extreme heat but add weight.

Balance thermal mass so swings are damped without causing internal condensation. Pair mass with interior ventilation paths that avoid uncontrolled drafts.

Adiabatic construction and entrance control

Minimize leaks and use a single controlled entrance to manage airflow and moisture. This adiabatic approach mimics a stable cavity and reduces evaporative stress on bees.

Continuous brood chamber geometry

Keep the brood area continuous to eliminate thermal bridges between frames. Fewer bridges lower convective losses and reduce fanning workload, improving foraging efficiency and colony health in field trials such as those in the Negev.

“Optimized insulation and tight joints shift energy from temperature control back into brood and nectar processing.”

- Use UV-stable outer finishes, insulated covers, and tight joints.

- Limit screened bottoms to seasonal use to avoid added evaporative stress.

- Source EPS or engineered bodies validated in field tests; avoid piecemeal add-ons.

Warre, Langstroth, or optimized insulated hives: choosing the right approach for heat

Different hive paths create distinct trade‑offs between simplicity, throughput, and thermal control.

Warre systems suit beekeepers who want natural comb and low disturbance. Small boxes mimic tree cavities, reduce heat load per unit, and keep lifts light. They use foundationless comb, require nadiring in spring, and harvest from the top in fall.

Langstroth advantages and practical management

Langstroth equipment provides removable frames and fast inspections. That boosts flexibility, supports larger honey flows, and fits U.S. supply chains. In hot zones, larger cavity volume needs added insulation and careful ventilation.

Engineering‑first performance

Purpose‑built insulated bodies deliver measured thermal gains: up to 5x better efficiency and lab dissipation near 0.01 W/dm²·°C. Field trials in the Negev show 2–3x harvests, 8x less feeding, and doubled brood area and population over years.

“Optimized thermal systems shift energy from cooling effort back into brood growth and honey processing.”

| Approach | Handling | Thermal Benefit | Typical Outcome |

|---|---|---|---|

| Warre | Low impact, light lifts | Smaller volume lowers heat load | Lower honey, natural comb |

| Langstroth | Fast inspections, scalable | Needs insulation upgrades | Higher yield, more management |

| Optimized insulated | Engineered bodies, single entrance | ~5x efficiency; 0.01 W/dm²·°C | More honey, stable brood, less feeding |

- Choose Warre for light handling and natural comb.

- Choose Langstroth for inspection speed and harvest throughput.

- Choose optimized insulated if maximum thermal control and resource efficiency are your priority.

If you run traditional boxes, start by adding reflective tops and insulated covers. Then plan a phased move to purpose‑built bodies if summer heat overwhelms colonies. For a practical guide to alternate horizontal systems, see this horizontal hive guide.

How to set up and manage hives in desert conditions

Practical setup and daily care make the difference between thriving colonies and repeated losses in arid zones. Start with placement and simple equipment choices that cut radiant heat and preserve internal moisture.

Siting, entrance orientation, and controlled ventilation

Site hives to get morning sun and afternoon shade. Avoid reflective walls or gravel that bounce heat back into the hive.

Orient the single controlled entrance toward prevailing breezes without creating drafts. Elevate stands off hot ground and use UV‑stable outer finishes.

Comb and brood handling; inspection cadence

Choose foundationless comb when you favor a natural approach, but expect gentler handling in high heat. Frames speed inspections and help target brood checks.

Plan checks in cooler hours. Keep openings brief and focused to keep internal temperatures steady and reduce disturbance.

Seasonal volume, feeding, and water

Use nadiring in Warre management to add space while keeping brood warmth. In framed systems, super carefully so brood area stays contiguous.

Provide constant, clean water with landing areas to cut fanning demand. Feed only during real dearths and avoid open syrup that invites robbing.

“Shade, controlled airflow, and reliable water are the most effective stress reducers in hot conditions.”

- Track weight, brood continuity, and flight activity to adjust cadence.

- A single controlled entrance and continuous brood geometry keep temperature uniform during seasonal changes.

Harvest expectations, colony growth, and risk control in deserts

Expectations around honey per hive should match local flows, equipment choices, and multi-year trends. Good planning helps you balance yield against long‑term colony health and survival.

Honey yield trade-offs: quality vs quantity

Warre systems often give less honey due to smaller volume and foundationless comb, but they are simpler to handle and light to lift. Optimized insulated units free energy from cooling and can produce 2–3x higher harvests in comparable field trials.

Benchmarks: expect large reductions in feeding—up to 8x less—and notable winter savings in many climates.

Wintering and colony resilience

Stable brood temperatures cut developmental stress and let colonies build before short blooms. Better thermal control can lower winter consumption by as much as 80%, improving survivability.

- Time harvests to short blooms; open a hive briefly to avoid heat shock.

- Use robbing guards, watch wax moth in weak colonies, and maintain entrance control.

- Track stores across years and move units to favorable microclimates when possible.

“Data‑driven choices that favor colony strength will usually outperform chasing maximum honey in a single season.”

Conclusion

When a unit holds temperature and moisture well, bees spend energy on growth instead of survival. That core rule lets colonies make more brood and produce steadier honey despite harsh heat. strong.

Choose a path that matches your goals: natural simplicity (Warre), scalable management (langstroth hive), or engineered, insulated units that give the largest gains.

Priorities: EPS or equivalent insulation, 30–70 mm wall thickness, adiabatic construction with a single controlled entrance, and continuous brood geometry. Pair equipment with smart siting, shade, clean water, and brief inspections to protect winter stores and build experience.

Audit your setup, fix the biggest thermal losses first, and share results with local beekeepers. Read the science of bee keeping to guide upgrades and monitor brood, water use, and forager traffic after each change.

FAQ

What are the main challenges bees face in hot, dry climates?

Heat, low humidity, and wide day–night temperature swings stress colonies. High ambient temperatures raise brood nest temperature and increase water and nectar needs. Low humidity can harden brood cappings and reduce nectar dilution. Strong solar radiation and reflective ground surfaces also increase hive internal temperatures unless shaded or insulated.

Which materials perform best to keep brood temperature stable in arid areas?

Insulating expanded polystyrene (EPS) and well-seasoned wood with added insulation both work. EPS offers strong thermal resistance per thickness, while wood combined with 30–70 mm of insulating layer balances thermal mass and breathability. Choose materials that reduce rapid heat transfer yet allow controlled moisture movement.

How thick should hive walls be to control heat and condensation?

Aim for 30–70 mm total effective thickness when combining structural boards and insulation. Thinner walls transfer heat quickly; thicker walls provide thermal buffering. Balance mass to avoid overheating during the day while retaining warmth at night, and ensure good ventilation to limit condensation.

Should I use a single controlled entrance or multiple openings in desert apiaries?

A single controlled entrance simplifies airflow management and reduces pest access. It makes shading and ventilating the hive more predictable. In very hot sites, add screened vents that can be closed when cool or humid to maintain brood conditions without excessive drafts.

Is a continuous brood chamber geometry better than stacked boxes in hot regions?

Continuous brood chambers reduce thermal bridges and let the colony manage brood temperature more efficiently, lowering colony energy use. They can improve insulation continuity and reduce disturbance from frequent box changes—benefits in extreme heat when minimizing bee exposure is critical.

Which system is best: Warre, Langstroth, or an insulated, engineered model?

Each has trade-offs. Warre hives are lighter, promote natural comb and smaller internal volume, and can suit heat-prone sites. Langstroth provides management flexibility and easier inspections under intensive management. Engineered insulated models (EPS or composite) offer superior thermal efficiency and may deliver multiple-fold performance gains in harsh deserts.

How should I site hives to reduce thermal stress?

Place colonies where afternoon sun is blocked, such as under shade trees or shade cloth, and on reflective ground covers to limit ground heat. Orient entrances away from prevailing hot winds and toward morning sun for early activity. Elevate hives slightly for airflow and to reduce ground radiation.

What inspection cadence works best when temperatures are very high?

Minimize inspections during the hottest hours. Inspect early morning or late afternoon when bees are calmer. Keep inspections short, plan work steps, and avoid excessive frame removal to reduce brood cooling and colony stress.

Foundationless comb or frames — which is smarter in arid climates?

Foundationless comb lowers material costs and allows natural comb spacing, which can aid thermoregulation. Frames give structural control and easier honey extraction with less disturbance. Choose by management style: small-scale or low-disturbance beekeepers may prefer foundationless; commercial operators often use frames.

How should I manage box changes across seasons in a hot climate?

Practice minimal disturbance. For Langstroth, super during nectar flows and remove or consolidate boxes before peak heat to reduce internal volume needing cooling. For Warre, use nadiring carefully and avoid over-expanding the cluster. Adjust timing to avoid heavy manipulations on extreme-heat days.

What feeding and water strategies reduce colony metabolic load?

Provide reliable water near hives to lower foraging stress. Offer high-quality syrup or pollen substitutes during dearths to limit brood rearing when resources are scarce. Efficient insulation and ventilation reduce energy spent on thermoregulation, cutting the colony’s overall metabolic demand.

How do honey yields compare between Warre, Langstroth, and insulated systems in dry climates?

Warre often yields smaller volumes but high-quality honey due to lower disturbance. Langstroth can produce higher yields with active management. Insulated engineered systems tend to improve net yields by reducing stress and brood losses, though local forage availability remains the primary driver of harvest size.

How should colonies be wintered in high desert areas?

High desert winters need energy conservation more than heavy insulation of temperate zones. Reduce entrances to limit drafts, keep stores accessible, and avoid unnecessary manipulations. Insulation and reduced internal volume help preserve cluster warmth during cold nights and hot days.

What common mistakes should new beekeepers avoid in arid regions?

Avoid over-ventilating, which can dry brood and increase energy use. Don’t leave hives in full afternoon sun without shade. Avoid frequent heavy inspections and over-expansion of boxes during heat. Finally, don’t neglect nearby water sources and forage planning—resources determine colony resilience.